- Overview

- Inquiry

- Related Products

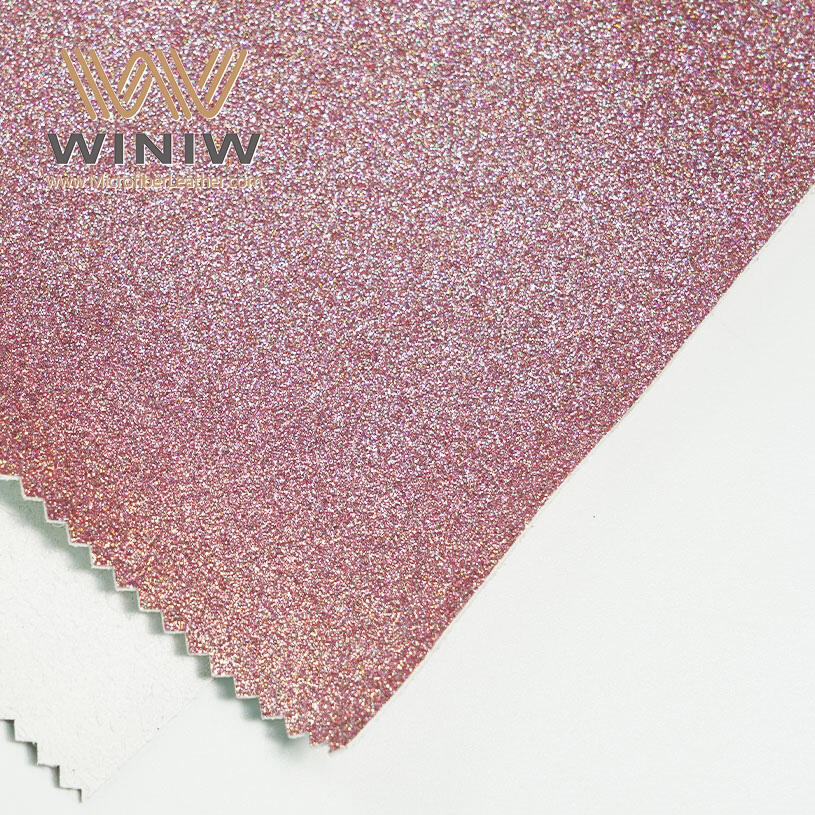

Product Introduction

Tear resistant PU leather handbags making materials are an excellent choice for anyone looking for durable and long-lasting bags. These materials are made from high-quality polyurethane (PU) which is known for its tear resistance capabilities. The tear-resistant feature of these materials makes it an ideal choice for making handbags, backpacks, and other types of bags that require high durability.

PU material look and feel like real leather but are much more affordable. This makes them an excellent choice for those who want the style and durability of leather without the cost. Furthermore, these materials are easy to work with and can be easily cut to size and sewn into any shape or design.

Product Details

Technological Progress Of PU Leather In The Production Of Bags

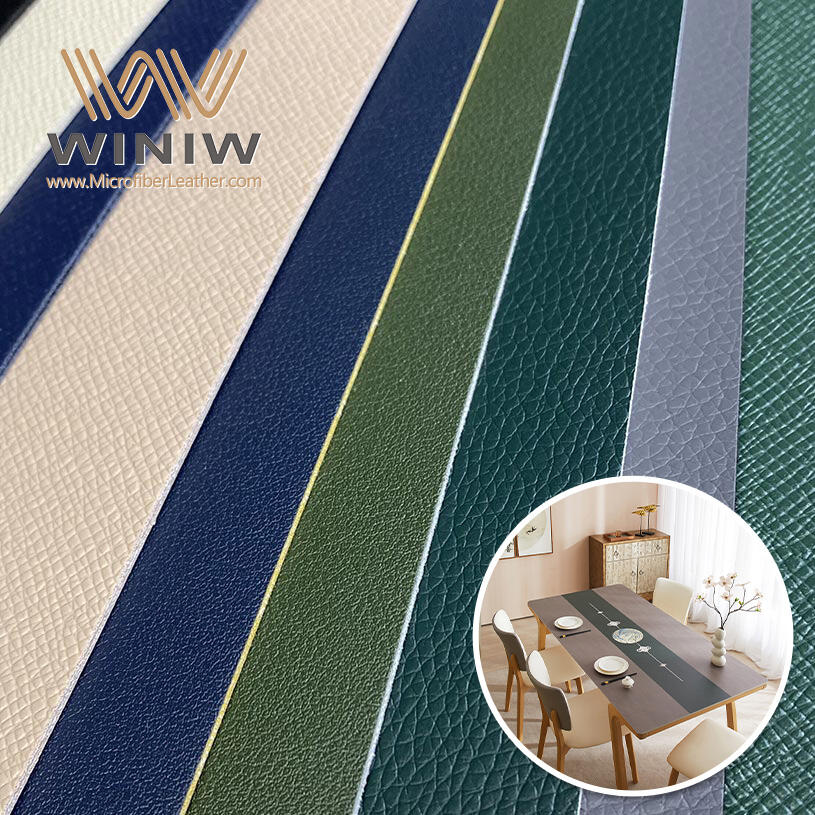

Adaptability and functionality: Modern PU leather technology has been able to adjust parameters such as porosity, cell size, cross-linking, coating thickness and filler ratio to meet various safety and environmental protection standards, and improve the aeration and moisture resistance of the product.

Diversified applications brought about by technological progress: With the development of science and technology, PU leather has been significantly improved in terms of microstructure, appearance and texture, physical properties and wearing comfort, making it not only suitable for high-end sportswear and footwear , luggage, furniture and other products can also meet the needs of more high-end markets.

About WINIW

FAQ

-

Q: How long for making color lab dip?

A: Around 3-7 days.

-

Q: Is your material real leather or faux leather?

A: Our WINIW microfiber eco leather is 100% synthetic, free of animal ingredients.

-

Q: How can you guarantee quality?

A: Always a pre-production sample before mass production; Always final Inspection before shipment;

EN

EN