quality hat embroidery machine

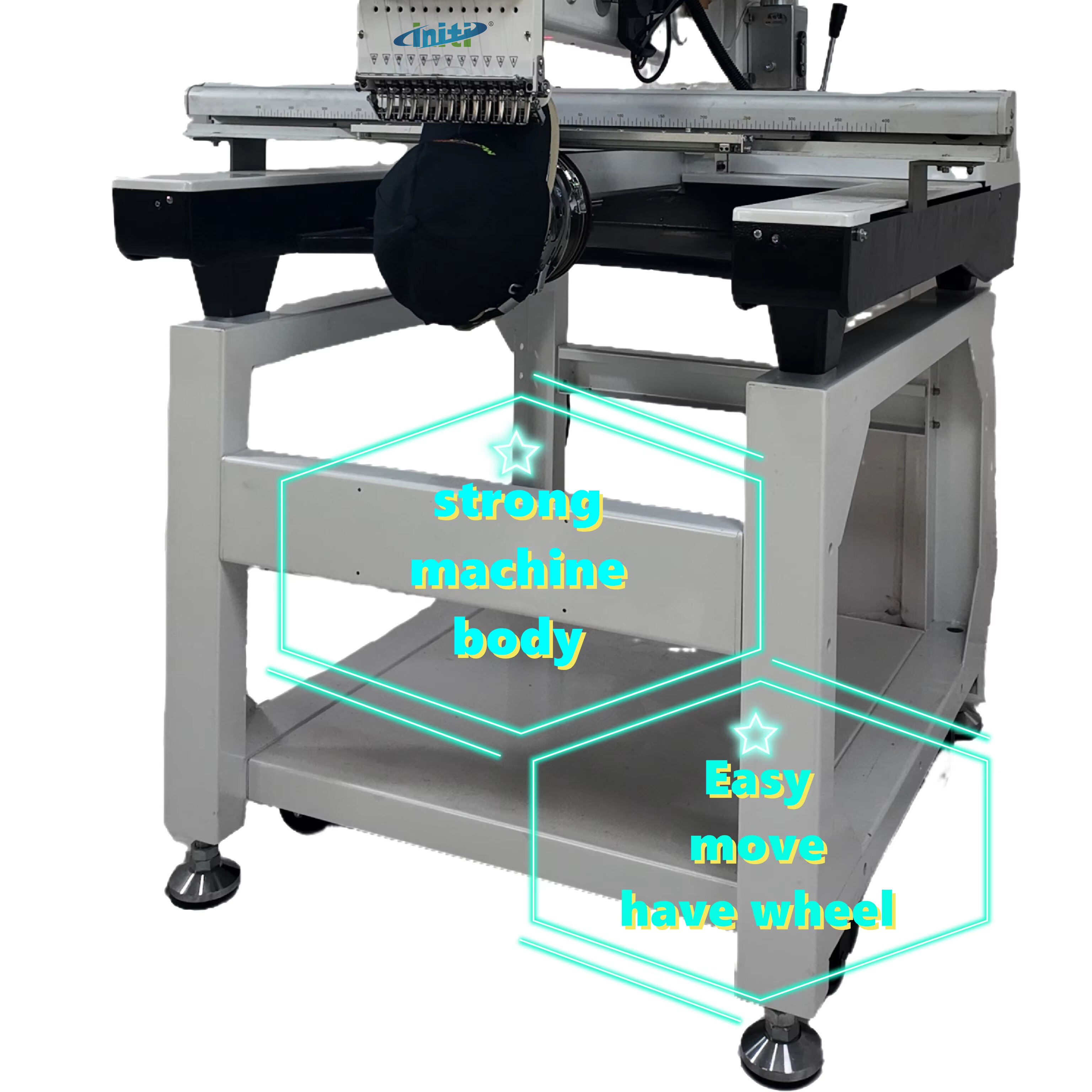

The quality hat embroidery machine represents a pinnacle of precision engineering designed specifically for creating intricate designs on various headwear styles. This advanced equipment combines robust mechanical capabilities with cutting-edge digital technology to deliver professional-grade embroidery results. The machine features multiple needle positions, allowing for quick color changes and complex pattern execution. Its specialized cap driver system ensures consistent tension across curved surfaces, while the high-speed servo motors maintain smooth operation at up to 1,200 stitches per minute. The machine comes equipped with an intuitive touch-screen interface that enables easy pattern selection, editing, and customization. Built-in memory can store thousands of designs, and USB connectivity allows for seamless pattern transfer. The automatic thread trimming system and built-in sensors help prevent common issues like thread breaks or tension problems. The machine's frame is constructed from industrial-grade materials, ensuring stability during high-speed operations and longevity in commercial environments. Advanced positioning technology guarantees precise design placement, while the adjustable presser foot accommodates various fabric thicknesses.